Taboo XT home

Taboo XL home

Construction notes

Construction tips

Ordering info

|

Aileron flutter can be a problem for full span ailerons on a DLG model

at high launch speeds. It is especially

true when launching a ballasted DLG model in strong winds, when the outer

wing panel reaches speeds well in excess of 100 mph. Aileron flutter

exibits itself as high frequency oscillations of the outer aileron which

can be heard as a low pitch buzz right after releasing the model. If

left uncured, this problem may cause premature servo failure. Even if no damage

is imparted to the model or the servos, flutter reduces your launch altitude

considerably.

The two main reasons for aileron flutter are 1) slop in the control system

(gear lash, pushrod slop), and 2) insufficient aileron torsional stiffness.

Make sure that your

control system is as tight as possible before you start reinforcing the

ailerons. Remove all slop from the servo and control horn holes by applying CA

to the hole and then breaking the pushrod free again. You can't do much about

servo gear lash short of replacing the servo with a better one, so you will

have to live with that. If tightening the control system did not help,

the only solution is facing the aileron leading edges with fiberglass.

This

creates a shear web between the skins of the aileron and inreases its

torsional stiffness by over 50% which practically eliminates the possibility of

aileron flutter.

|

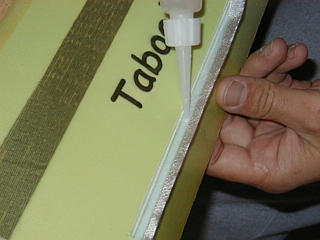

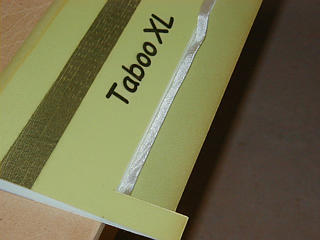

Start by preparing a strip of fiberglass slightly wider than

the the thickness of the aileron. The strip must be cut at 45

degrees to the fibers. Use a sharp X-acto knife and metal

straight edge to cut the strip. Be careful when handling

the strip as it is very easy to deform it by stretching

and nearly impossible to return it back to the original

shape. Use a tight weave fiberglass with 2oz/sq.yd. weight.

|

|

|

Position the wing panel on the table so that the aileron is

hanging off the edge and is deflected down.

Lay the strip on the wing along the hinge line. Start

at one end of the aileron and lay the strip onto the

surface of the foam on the aileron's leading edge.

|

|

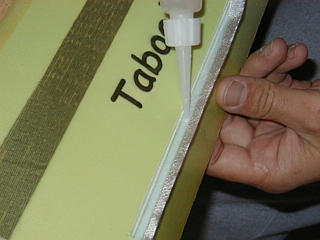

Do not try to lay the entire strip onto the LE. Do it

only a couple of inches at a time. The strip does not have to

be as long as the aileron. You can use short pieces and

butt them together as you apply glue (see next step).

|

|

|

Start from the end of the aileron and

apply foam safe CA glue to the fiberglass strip. Be careful

to apply just enough glue to wet out the fiberglass. Do not

let the glue flow onto the hinge line. This will immediately

result in a stiff hinge and will require a lot of effort

to return the hinge back to the flexible state.

|

|

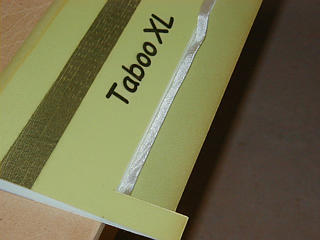

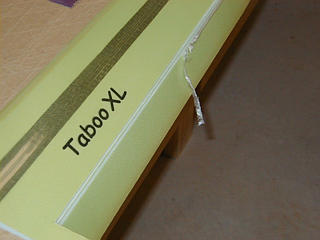

As you wet out the first portion of the strip, continue

laying it down onto the foam and applying foam safe CA glue

until you get to the tip.

|

|

|

The reinforcement strip does not have to go all the way to the wing

tip. You can stop about 2-4 inches short of the tip.

|

|

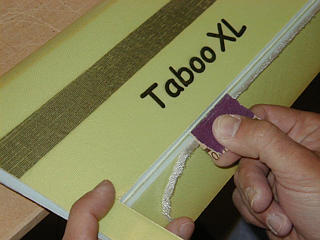

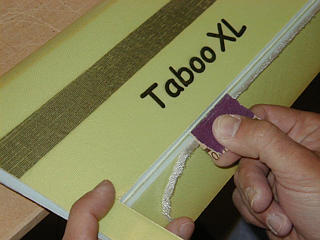

Once the entire strip is glued down, and the glue is

completely set, use a piece of sanding paper to "cut" off

the excess fiberglass. Press on the edge of the aileron and

move the sandpaper along the hinge line until the excess

fiberglass falls off.

|

|

|

Continue sanding the edge until you remove all of the excess

fiberglass. Using sandpaper instead of a knife or a rasor

blade automatically ensures that the reinforcement strip

will not stick out above the wing surface, and allows you

to remove all glue bumps as you go.

|

|

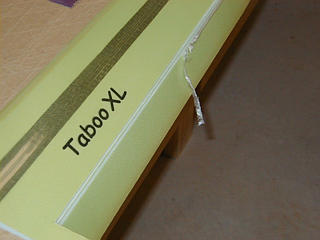

The final result is a much stiffer aileron, and no flutter.

Repeat the procedure with the opposite wing to be sure that

both wings have equal aileron stiffness. It is easier

to do the described procedure before assembling the wing,

but it can also be done successfully on a finished wing. If

you have flown your DLG for a while and your launching

technique improved to the point that you are experiencing

flutter, it is time to take your wing back to the building

table, remove the servos and pushrods if possible, and reinforce

the ailerons with fiberglass.

|

|

|